Materials & Finishes

Everything starts with you and the designer. Since pieces are not pulled from inventory, but essentially “made-to-order”, the fabric, firmness of the foam, finished texture and color will be unique to you. No one else will have furniture like yours.

There are hundreds of color finishes and fabric options which creates thousands of options. Come in, sit down–literally all over the place – look and touch the fabrics and finishes.

Materials

Colors

Fabrics

Metals

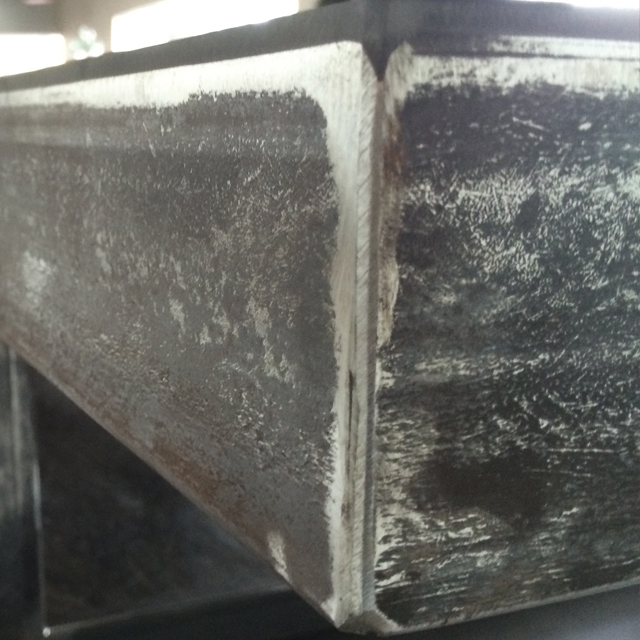

Carbon Footprints metal pieces are fabricated from 14 and 16 gauge steel to be heavy enough to withstand almost anything Mother Nature throws at it. All corners, edges and connection points of the furniture are fully welded and ground smooth for a contemporary and clean edge.

For outdoor metal furniture we recommend powder coating.

Pieces can also be left “natural” to rust, or have an oiled finish. These two finishes can, and will “exude” a rusting effect that can stain the horizontal surface on which they sit. Surfaces need to be considered thoroughly when designing with this type of look and finish.

Woods

Woods used in our furniture strive to always be recycled or reclaimed.

Locally we find mesquite, ironwood, rosewood, acacia, and pine (many various species).

Many of the local woods come from landfills where development has decided to scrape the landscape and start over. Our sawmill partners either search this wood out, or other concerned designers bring these woods in on consignment, which are planked or custom cut for various designs.

Other woods that have been salvaged from around the country include walnut, redwood, barn wood, and teak.

There are various finishes for all woods. Pieces that are “under cover” can use more organic finishes saturating the wood with linseed, teak or tongue oils. For a more sealed finish, polyurethane in satin, semi-gloss or glossy, depending on your tastes, after staining to your desired color.

Other pieces that will be in the open, will require stronger finishes that will contend with sun, heat, water and dust.

High Pressure Laminate (HPL)

(HPL) is a flat panel, based on thermosetting resins, homogeneously reinforced with recycled paper and manufactured under high pressure and high temperatures.

Carbon Footprint uses the architectural grade of HPL custom graphic applications for chairs and table tops. This grade of HPL is UV resistant and extremely weather resistant. Neither sun, rain (including acid rain) nor moisture have any effect on the material’s surface or core. Since surfaces are not affected by moisture they are not susceptible to weathering, mold or rot.

The smooth panel has a pore free surface structure, ensuring that practically no dirt accumulates. Whatever the color, print, graphic or design on the surface, the edge is always black.

Composite Woods

Mimicking the natural beauty of wood, but made from 100% engineered plastic, synthetic wood has the same natural color variations and random grain pattern as real timber but without any of the associated maintenance or fading problems.

Unlike solid wood and other composite wood materials, synthetic wood is truly zero maintenance, requiring no staining, painting or finishing to retain its original good looks.

The 100% plastic formulation is both rigid and strong. This means zero water absorption, thus eliminating risk of rotting, mildew, staining, splitting or cracking.

Synthetic wood incorporates reclaimed EPS (expanded polystyrene or styrofoam), which comes primarily from appliance and electronics packaging that would otherwise be burnt or buried in a land fill. Synthetic wood is also 100% recyclable and can be reprocessed or recycled at the end of its useful life.

Finish Colors

Powder coating is a free-flowing, dry powder that is applied electrostatically to metal and is then "cured" under high heat to allow it to flow and form a skin. This process creates a uniform, incredibly durable, high-quality, and beautiful finish.

Powder coating offers literally hundreds of colors and textural options that will compliment fabrics and existing home accents.

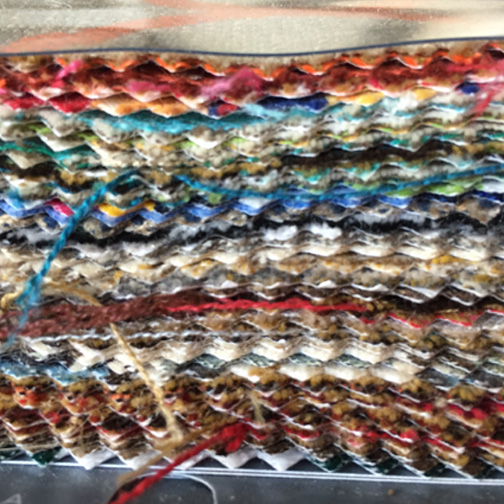

Fabrics

A good starting point when considering how environmentally friendly fabrics are is to consider the useful life of the fabric. How long will the end user be able to use the fabric before it begins to show signs of wear and needs to be replaced.

All outdoor pieces are made with Sunbrella®, Donghia® or Perennials®. These fabrics are made from 100% solution-dyed acrylic with soil-resistant finishes.

Cushion sets start with a standard 4” deep seat cushion and 3” deep back with welting, ties and zipper backs. These are designed to be interchangeable for lounge chairs, love seats and couches.

There are three price points in the fabrics to choose from - based on level of detail and color in the fabric’s design – Classic, Grand and Deluxe.

Pricing for a cushion set starts at $590 for Classic; $790 for Grand; and $970 for Deluxe. We’ll show you all the various options and help you understand the differences, but it’s your choice.

Cushion Inserts (foam)

In Arizona, and any other “dry” climates, mold and mildew is usually not an issue, so a standard foam works when using solution dyed acrylic fabrics. There are four density choices – 15, 23, 30 and 50 – soft to very firm– and everyone has their own taste. Jamie likes 50 and Todd prefers 30.

For pieces that will reside in more humid and wet climates Dryfast® foam is what we recommend. The cost difference is less than 2% in the overall price of a set of cushions, and in wet climates, you’ll be much happier and the life of the cushions will be much longer.